BoldInspect - Industry 4.0 Quality Control Platform

Next Generation Industrial Quality Control

About BoldInspect

Today’s production processes are ever more time sensitive on delivery, require significant flexibility for last minute changes, and at the same time are seeing ever increasing demands on quality control and process interaction from stake holders that are on site or remote – and all in real time.

BoldInspect is a web-based software platform designed for quality control in manufacturing. It provides access to CAD data in the browser, allowing anyone in the factory to view and analyse product parts during R&D, pre-series and series manufacturing. BoldInspect combines CAD data with measurement data produced by devices ranging from high-precision laser scanners to digital callipers, providing users with a comprehensive view of their manufacturing processes, easily viewable on-the-go via Apple iPad Pro and its LiDar.

Highly customizable, BoldInspect can be adapted with custom integrations and features that can be tailored to specific manufacturing processes. This flexibility allows users to optimize their quality control efforts and improve efficiency throughout their operations in real time, reducing waste and increasing profitability.

BoldInspect is a web-based software platform designed for quality control in manufacturing. It provides access to CAD data in the browser, allowing anyone in the factory to view and analyse product parts during R&D, pre-series and series manufacturing. BoldInspect combines CAD data with measurement data produced by devices ranging from high-precision laser scanners to digital callipers, providing users with a comprehensive view of their manufacturing processes, easily viewable on-the-go via Apple iPad Pro and its LiDar.

Highly customizable, BoldInspect can be adapted with custom integrations and features that can be tailored to specific manufacturing processes. This flexibility allows users to optimize their quality control efforts and improve efficiency throughout their operations in real time, reducing waste and increasing profitability.

Thank you! Your submission has been received!

Oops! Something went wrong while submitting the form.

Benefits

Saving Time And Money While Improving Quality

Improve quality control

clear insight into 3D measurement data, not constrained by paper printouts, with viewing from any angle, zoom level and detail – including real-time scaling of tolerance heat maps

Reduce pre-series costs

faster turnaround times from measuring to making changes when preparing the series manufacturing process

Increase manufacturing flexibility

by giving workers on-line access to CAD drawings, parts catalogues and measurement data, everyone can work with up-to-date data

Transform manufacturing workflows with digitalization

eliminates printing and distributing drawings, integrates with specific instruments and devices and fits within your manufacturing process

Protect Intellectual Property

prevents circulating sensitive CAD models to non-R&D personnel, and reduces the level of detail downloaded to end-user devices to ensure further IP protection

View 3D data without additional CAD/CAM licenses

We’re an extension of your customer service team, and all of our resources are free. Chat to our friendly team 24/7 when you need help.

Comprehensive quality control and enhanced manufacturing efficiency

Product Navigation

all product parts organized in fully customizable tree views with custom images to depict categories in an easy-to-understand manner

Product Documentation

CAD drawings, PDFs and other files stored conveniently with each part

Measurement Visualisation

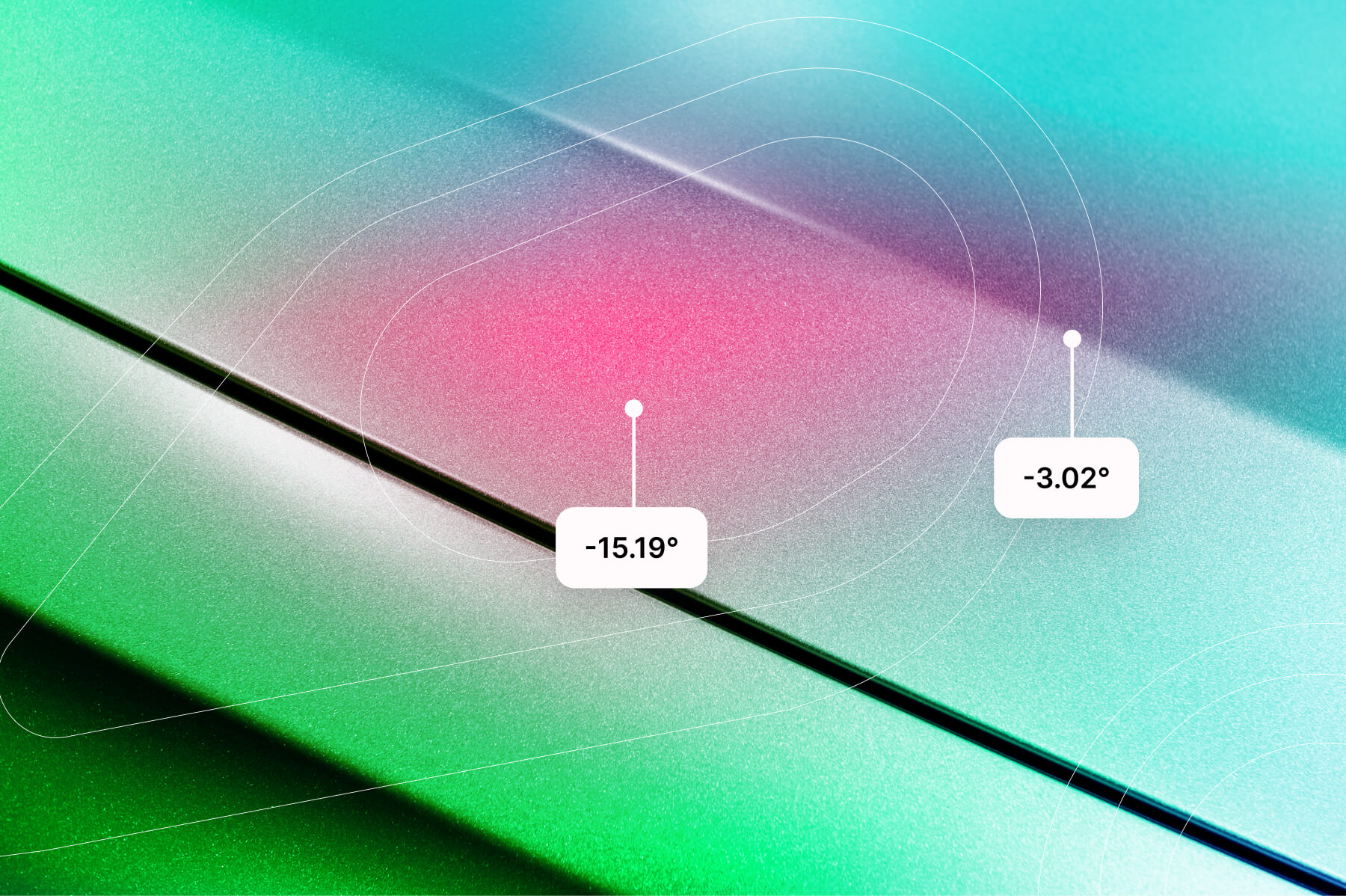

3D views of quality control data as heat maps or inspection points with data callouts

Augmented reality

See actual parts with a blended view of CAD models and measurement data, thanks to LiDAR-powered Apple iPad Pro tablets

Mobile Data Access

anyone in the factory can access 3D CAD data in an easy-to-use intuitive web user interface which works on mobile devices such as the Apple iPad Pro

Use cases

Cutting-edge features for advanced analytics

Automotive

Parts suppliers

High-precision manufacturing

Light engineering

Defense

About us

BoldInpect was created by a team of information management and visualisation specialists and programmers at BoldBrick. Led by founder Ondřej Tučný, these specialists in document sharing and management have enjoyed considerable success with solutions for the banking, property development or automotive industries. BoldBrick’s document management solution for SKODA AUTO – MilkyWay – is a Microsoft Awards winner in the Collaboration and Project Management Category.

BoldInspect is a natural yet innovative evolution in information sharing and management, concentrating on enabling visualisation in AR, interpretation and sharing of quality control data in real time, remotely and across multiple platforms, both streamlining and improving the quality control process. Its first commercial implementation in the form of e-Protokol at SKODA AUTO immediately won their internal IT Project of the Year Award in 2021.

BoldInspect is a natural yet innovative evolution in information sharing and management, concentrating on enabling visualisation in AR, interpretation and sharing of quality control data in real time, remotely and across multiple platforms, both streamlining and improving the quality control process. Its first commercial implementation in the form of e-Protokol at SKODA AUTO immediately won their internal IT Project of the Year Award in 2021.

Contact us

Our friendly team would love to hear from you.